The Benefits of Automated Printed Circuit Board Assembly

Printed circuit boards are used in a variety of modern electronics. Without PCBs, most of these electronics will be impossible to manufacture and very bulky. With technological development, printed circuit boards are now much easier to assemble and mass produce owing to automation and machines. In the past PCB manufacturing was done by hand resulting in less consistency in quality and slower production. Automated PCB fabrication offers a wide range of benefits for businesses, they include the following.

Lower Overall Costs

With automated PCB manufacturing processes, you can expect lower costs. Most manufacturers use exclusive software for assembling circuit boards digitally before the actual mass production. This helps to lower the risks of delays and errors. With this phase of production, the PCB designers are able to fix any error which eliminates possible problems when the actual production begins. With automated assembly, fewer employees are required to handle the task. This can also result in financial savings for assemblers and lower the cost of PCB production.

Prevents or Eliminates Human Error

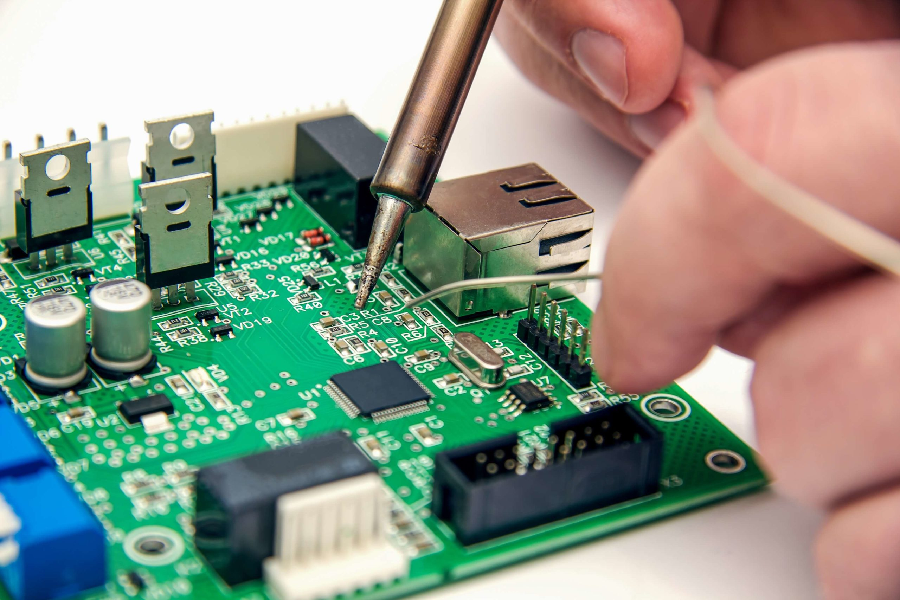

The PCB fabrication process is such as delicate task and can be quite challenging. The PCB assembly process needs great attention to detail. The circuit boards and components are becoming smaller over time and all these parts should be correctly soldered to avoid errors. Although mistakes may happen, automated machines are designed to handle delicate and repetitive tasks and are unlikely to make mistakes compared to employees. With automated PCB manufacturing processes, the work will be done accurately and in less time.

Shortens the Product Development Cycle

The time needed for hand-assembly will vary depending on the size and complexity of the board. This means that PCB boards will be produced in inconsistent timeframes. Hand-assembled PCBs will always take more time to produce and this can affect production of devices. With automated PCB manufacturing processes, you can be confident that your boards will be produced in superior quality and within the shortest time possible.

Quality is Consistent

Automated PCB fabrication machines are designed and programed to carry out the same tasks repeatedly. Furthermore, their accuracy and the quality of the circuit boards are better and more consistent when compared to hand-assembled boards. With automation, you can maintain the likeliness of every board that is produced and you are assured of consistent quality whenever you partner with a PCB assembly company.

Ideal for Mass Production of PCBS

With automated production of circuit boards, you can reduce the production costs and time. As a result, automated processes will create higher volumes within no time. If you need mass production of PCBs, it is more effective to choose automated assembly services. You can be confident that your boards will be more effective and will be delivered timely and in a consistent manner when compared to hand assembling process.

To reap the benefits of automated PCB manufacturing processes, you need to adhere to some set design guidelines. This is important whether you are working on a small or large order. Always remember that automation will not make up for a poor design. Therefore, you must ensure that the design stage is done properly to take advantage of the automation process later on. Eliminating design problems will ensure little rework which mat delay the whole production process and delivery time.